Spherodise Annealing

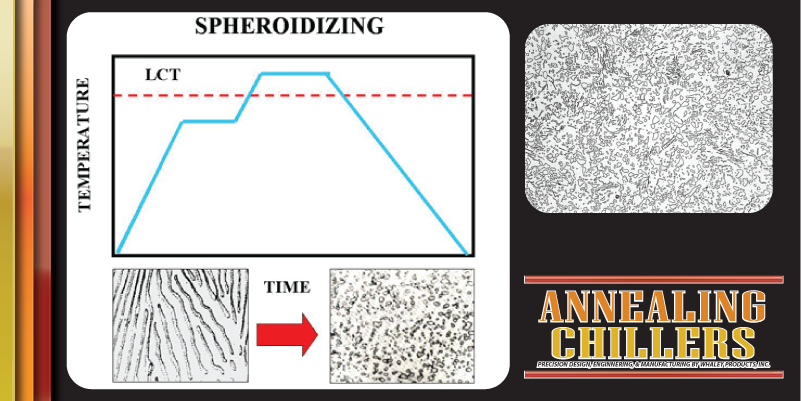

Spherodise annealing involves the heat treatment of carbon steels and iron-based alloys. As in most annealing processes, this process is used to increase the ductility and machinability. Temperatures are held at a constant temperature which is slightly below the temperature at which the solution is a solid. The temperature can be held for 15-25 hours depending on the steel. The temperature will vary by material. At this time, the microstructure of the alloy, or carbon steel will become sphere like. Then the metal is cooled slowly.

Components found in iron based alloys are pearlite and graphite. When spherodise annealing starts the pearlite starts to change. It then converts into ferrite and cementite. Graphite becomes spheroidal in shape during this process. These spheroidal structures are larger and more spaced out than the pearlite in the beginning of the process. Spherodise annealing is used in bridge cables, machinable steel and rail road tracks.