Annealing Information and Materials Used

Annealing treatment is used to reduce the hardness of a material, increase the ductility, and make an object more workable. This process can be known as “softening”. Annealing has three different process attributing to the softening of metals. During these three phases crystals inside the grains of metal change. The first step is called recovery. Recovery eliminates defects that are inside the grains of the metal, physical properties of cold worked material are restored, and takes place at low temperatures. Recovery also relives stress from cold worked material. Recovery occurs in the stored energy of the material. During recovery polygonisation occurs. Polygonisation is the formation of sub grains within the grains of metal, after being worked. Structures become mobile at higher temperature during polygonisation.

Recrystallization is the creation of strain-free grains in metal. Recrystallization temperatures are defined as a specific temperature at which 50% of material recrystallizes in an hour. The stressed strains that make to product brittle are replaced. The switching of these structures allow the metal to be punched, stamped, shaped or bent easier.

The third step of annealing is grain growth. This is when the average grain size increases into a polycrystalline material. The size of the grains is indicative of the elements contained in the metal. Grain growth is also dependent upon on temperature. At high temperatures grain growth is increased due to grain boundary surface energy.

Different types of annealing exist. Most of them have similar process and deal with different metals. Copper, aluminum, brass, steel and silver are popular metals and will have different recrystallization temperatures. Steel can go through two different annealing process. These are called process annealing, and sub critical annealing.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

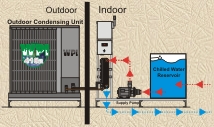

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |