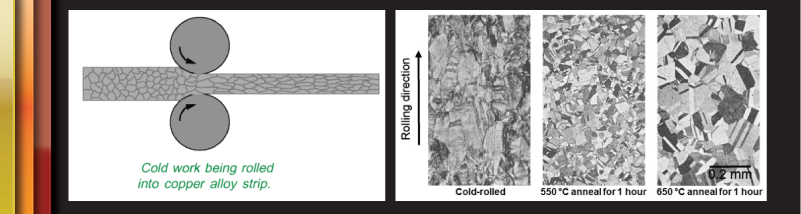

Process Annealing

Process annealing is the heating of metal and cooling it slowly. This process is to restore ductility of metal that has been lost during the process of cold working. Cold working strengthens a metal by manipulating the crystal structure with temperatures below a metal’s mechanical stress point, and recrystallization point. The only thing that changes during annealing is the size, shape, and distribution of grain structure. This temperature varies upon the metal being used. For example, temperatures will differ among steel, aluminum and copper. Most temperatures are between 500°F- 1400°F.The cold temperatures don’t allow for crystalline structures to move. Strength and hardness are improved by cold working, but ductility is not. Surface finish can also be improved of the metal by cold-rolling, and cold drawing.

Cold working can cause metals to become too brittle work with. Process annealing allows for the heating of a metal below its austenitizing temperature. Stresses are removed from the crystal structure formation and slowly cooled. The metal is cooled in the furnace to avoid new stresses. The slow cooling allows for material to ease into different formations that have been created during process annealing.

Whaley Products

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

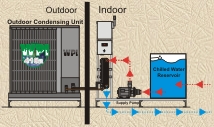

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |