In metallurgy, annealing is considered a heat treatment. Metallurgy is the understanding of physical and chemical behaviors of metallic elements, their compounds and other mixtures called alloys. Starting with the Egyptians in 3000 BC metalworking has spread to many different cultures. Over the course of many eons, metallurgy has adapted along with technology.

Annealing is the process in which high temperatures of heat is used to alter the physical and sometimes chemical composes of a material, usually metal. It is used to increase the ductility and reduce the hardness of metal to make it more workable. The material is heated to a crystal point that allows for recrystallization to occur. The atoms found in the material move in a crystal lattice and the number of dislocations decrease. The material takes on new properties and loses others. Once heated and the change has occurred it is then cooled.

Annealing is composed of different types. Process annealing, stress relief, spherodise and isothermal annealing are used in a plethora of industries. The process is not just used for manufacturing of metals. Glass and plastic industries use annealing as well. Glass is annealed to relive and residual internal stressed caused during manufacturing. Slowly cooling the glass allows for uniform cooling. This process is similar to annealing plastic. Plastic annealing allows manufacturers to get rid of a mishaps of stresses caused in their products. Annealing is used for many different materials and manufacturing industries.

Packaged Chillers Non-expandable (integrated pump tank) 1.5Ton – 20Ton Single / Dual Circuits Single / Dual Pumps |

SAE Series Modular Chillers Expandable (pump & tank on separate skid) 1.5Ton – 200Ton Single / Dual Circuits |

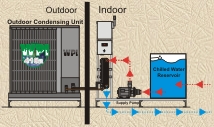

SAR Series Split Chillers Expandable (Outdoor Condensing Unit) (pump, tank, evaporator on indoor skid) 1.5Ton – 200Ton Single / Dual Circuits |