Full Annealing

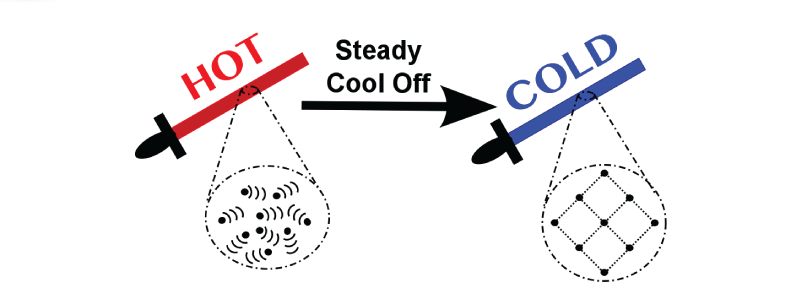

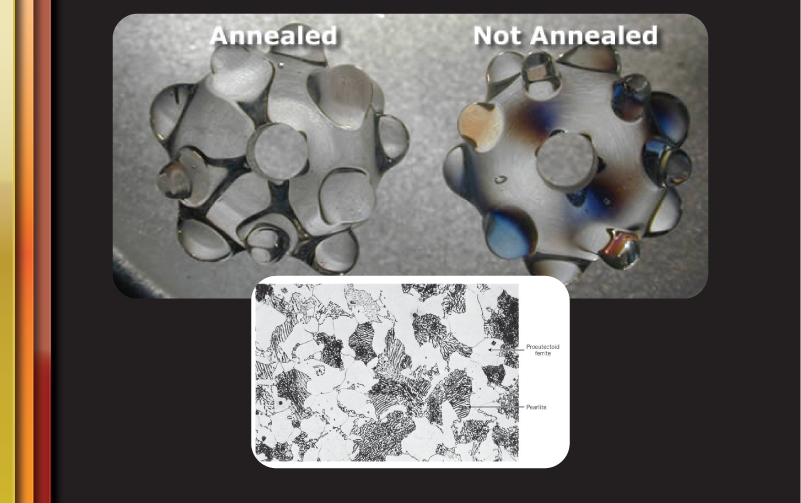

Full annealing is used to relieve internal stresses and refine the grain size of a metal, or nonferrous metal. Once the full annealing process is finished, the material becomes homogeneous and has a uniform chemical composition. This means the elements inside of steel are more stable and create a unvarying structure. Full annealing is used to make steel suitable for undergoing other heat treatment processes like normalizing and hardening. The metal is heated to high temperatures and cools very slowly, normally inside a furnace. Full annealing is usually only needed for high alloy steels, cast irons and complex alloys. Once full annealing is done, coarse crystals of ferrite and pearlite.

Full annealing is the most common annealing process. This process is used mostly on steels but can also be used on nonferrous materials as well. Nonferrous materials can include alloys. Nonferrous metals are mostly used for their low weight, higher conductivity, and nonmagnetic property. These metals are perfect for full annealing. Full annealing reduces hardness and can increase ductility. Heat temperatures for full annealing vary from alloy to alloy. Steels have temperatures that can be heated from 1526°F to 1742°